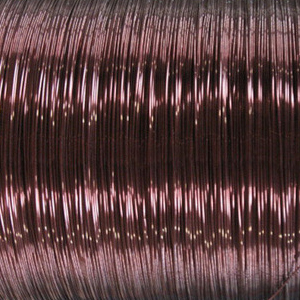

FeaturesThe wire's main feature is its ability to compact with the input of heat when wound. It is a C200 base wire with a top layer of thermal adhesive varnish. A POLYESTER or POLYESTER-IMIDE base layer, a second layer of POLYAMIDE-IMIDE, and a final layer of AROMATIC POLYAMIDE. The C200 base provides outstanding thermal properties. |

|

|

Standards |

Grades |

|

|

IEC / DIN EN 60317-0-3 |

1-2 |

|

Technical Specifications |

||

| Parameter | Unit | Value |

|---|---|---|

| Section | - | Round |

| Material | - | Aluminium |

| Standard | - | IEC-60317-0-3 MW35-A EDERFIL BECKER SPECS. |

| UL Certificate | - | - |

| Thermal class | - | 200 |

| Enamel polymer | - | PEI+PAI+PA |

| Grades | - | 1-2 |

| Diameters | mm | 0,236-2,00 |

| Parameter | Unit | Point IEC | Test conditions | IEC value | Valor real (Ø0,80mm) |

|---|---|---|---|---|---|

| Conductor diameter | mm | 4.1 | - | 0,792 - 0,808 | or within the range defined by customer |

| Overall diameter | mm | 4.3 | - | 0,850 - 0,882 | or within the range defined by customer |

| Elongation | % | 6 | - | 12 | 20 |

| Springiness | grades | 7.1 | - | Not applicable | - |

| Flexibility and adherence | - | 8 | - | Ø2,4mm | Ø0,80mm |

| Resistance to abrasion | N | 11 | - | - | - |

| Sliding force | gr | - | - | - | - |

| Peel test | turns | 8 | - | - | - |

| Parameter | Unit | Point IEC | Test conditions | IEC value | Valor real (Ø0,80mm) |

|---|---|---|---|---|---|

| Breakdown voltage | V | 13.2 | Twist | 2600 | 5000 |

| Electrical Conductivity | MS/m | 5 | - | 35,5 - 36,2 | ≥35,85 |

| Continuity of insulation | Faults | 14 | 30m 500V 6µA | 10 | 0 |

| Parameter | Unit | Point IEC | Test conditions | IEC value | Valor real (Ø0,80mm) |

|---|---|---|---|---|---|

| Temperature index | °C | 15 | - | - | - |

| Dielectric dissipation factor (tg δ) | °C | - | - | - | 140 |

| Cut-though | °C | 10 | - | - | - |

| Heat shock | - | 9 | 220º 30min | Ø2,4mm | OK |

| Parameter | Unit | Point IEC | Test conditions | IEC value | Valor real (Ø0,80mm) |

|---|---|---|---|---|---|

| Solderability | °C | 17 | - | Not applicable | Not applicable |

| Resistance to transformer oil | - | 20 | - | - | No |

| Resistance to refrigerants | - | 16 | - | - | Limited |

| Resistance to solvents | - | - | - | - | Not applicable |

| Heat bonding | - | - | - | - | >180 |

[1] Due to the variety of individual applications, we cannot make any generally binding commitments regarding compatibility. We recommend testing compatibility with the materials used.

Spool |

|

|---|---|

| (Type) | Nominal weight |

| A 250/400 | 45kg-15kg |

| A 315/500 | 90kg-30kg |

| A 400/630 | 180kg-60kg |

| A 500/800 | 360kg-120kg |

Download product data sheet |

![[Hero] ROUND-AL-C200 THERMO(Image)](/images/p/product-ederfil-becker.jpg)