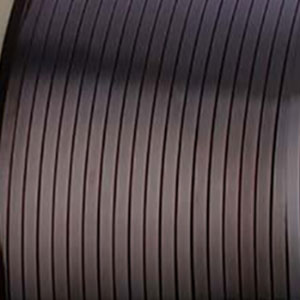

FeaturesIt is an enamelled flat with high mechanical, thermal and chemical properties. Structurally, the flat consists of a POLYESTER or POLYESTER-IMIDE base varnish and a POLYAMIDE-IMIDE top layer. Each layer of varnish gives the final wire excellent properties for the industry. Mechanically, it is characterised by its excellent resistance to abrasion and high flexibility, making this wire capable of windings on demanding curvature radii. Thermally, it is capable of withstanding high working temperatures and occasional overloads. Chemically, it is compatible with most commercial impregnation resins and oils, coolants and cleaning fluids. |

|

|

Standards |

Grades |

|

|

IEC / DIN EN 60317-73 |

1-2 |

|

Technical Specifications |

||

| Parameter | Unit | Value |

|---|---|---|

| Section | - | Flat |

| Material | - | Aluminium |

| Standard | - | IEC-60317-73 MW36-A |

| UL Certificate | - | E93551 |

| Thermal class | - | 220 |

| Enamel polymer | - | PEI+PAI |

| Grades | - | 1-2 |

| Cross-section | mm2 | 18 - 75 |

| Parameter | Unit | Point IEC | Test conditions | IEC value | Obtained values (14,00 x 6,00mm) |

|---|---|---|---|---|---|

| Conductor dimension Width | mm | 4.1 | - | 13,900 - 14,100 | or within the range defined by customer |

| Conductor dimension Thickness | - | - | - | 5,950 - 6,050 | or within the range defined by customer |

| Overall dimension Width | mm | 4.3 | - | 14,020 - 14,270 | or within the range defined by customer |

| Overall dimension Thickness | - | - | - | 6,070 - 6,220 | or within the range defined by customer |

| Increase in dimension Width and Thickness | mm | - | - | 0,120 - 0,170 | 36 |

| Elongation | % | 6 | - | ≥15 | Not applicable |

| Springiness | °C | 7.1 | - | Not applicable | <5 |

| Flexibility and adherence | - | 8 | - | 15% <1xWidth | Lack of adherence <1xWidth |

| Mandrel winding test on Width | - | - | - | Mandrel 5 x Width | Mandrel 3 x Width |

| Mandrel winding test on Thickness | - | - | - | Mandrel 4 x Thickness | Mandrel 3 x Thickness |

| Parameter | Unit | Point IEC | Test conditions | IEC value | Obtained values (14,00 x 6,00mm) |

|---|---|---|---|---|---|

| Breakdown voltage | V | 13.2 | Steel ball bath | ≥2000 | ≥3000 |

| Electrical Conductivity | MS/m | 5 | - | ≥35,5 | - |

| Continuity of insulation | Faults | 14 | - | - | <7 in 100m |

| Parameter | Unit | Point IEC | Test conditions | IEC value | Obtained values (14,00 x 6,00mm) |

|---|---|---|---|---|---|

| Temperature index | °C | 15 | - | 220 | 220 |

| Dielectric dissipation factor (tg δ) | °C | - | - | - | - |

| Heat shock | - | 9 | 220ºC 30 min | Mandrel 6 x Thickness | Ok |

| Parameter | Unit | Point IEC | Test conditions | IEC value | Obtained values (14,00 x 6,00mm) |

|---|---|---|---|---|---|

| Solderability | °C | 17 | - | No aplicable | No aplicable |

| Resistance to transformer oil | - | 20 | - | - | Sí |

| Resistance to refrigerants | - | 16 | - | - | Sí |

| Resistance to solvents | - | - | - | >H | 4H |

| Heat bonding | - | - | - | - | 180 |

[1] Due to the variety of individual applications, we cannot make any generally binding commitments regarding compatibility. We recommend testing compatibility with the materials used.

Spool |

|

|---|---|

| (Type) | Nominal weight |

| K 355 | 45kg |

| K 500 | 90kg-30kg |

| K630 | 180kg-60kg |

| K 710 | 180kg-60kg |

| K 800 | 240kg |

Download product data sheet |

![[Hero] FLAT-AL-C220-WXT(Image)](/images/p/product-ederfil-becker.jpg)